Our strength

- Home

- /

- Our strength

High technology for ultimate performance

Our rims, which have been used on numerous race-winning bikes around the world, are top-grade rims designed to be stable, lightweight, strong, and flexible.

Rims are an important part that affects the performance of a machine.

In order to meet contradictory requirements of high strength and light weight, we develop our rims with a lot of tests and analyses, and manufacture them with the most advanced special technology.

Commitment to strength and lightweight

Using the highest strength aluminum alloy developed in collaboration with a material manufacturer

To meet the contradictory requirements of light weight, strength, and flexibility, we worked with a material manufacturer to develop a special aluminum alloy

Design with special attention to detail

We use multiple materials and profiles depending on the purpose of use to achieve the required strength at the optimum weight.

For some products for competition use, the thickness of each part is adjusted to achieve further weight reduction without compromising strength.

Product design and development using the most advanced technology

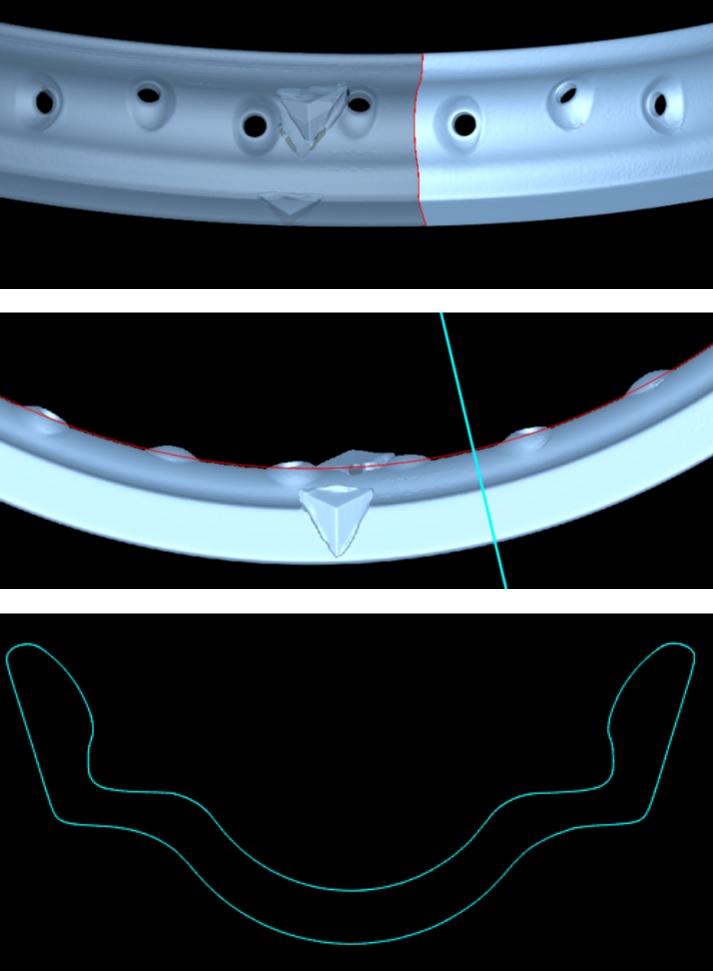

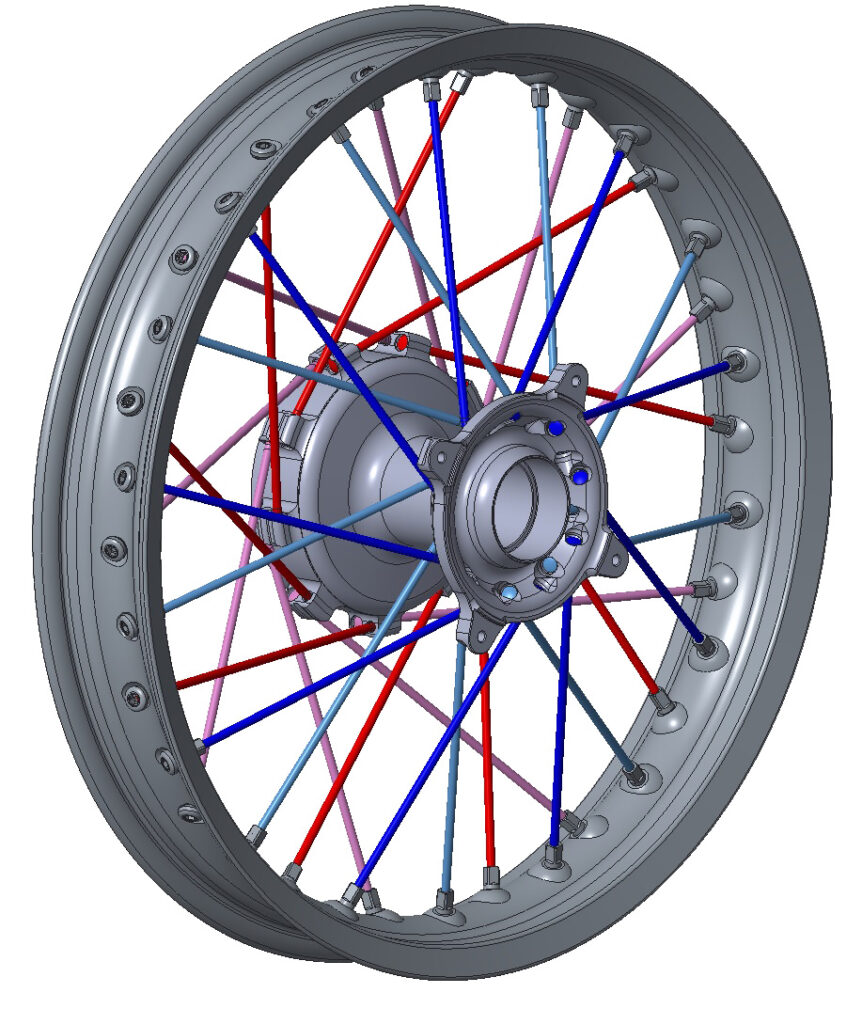

Rim Product Design in 2D and 3D

We do product design in both 2D and 3D.

This allows us to study the product design in more detail and keep working to provide the best quality and functionality.

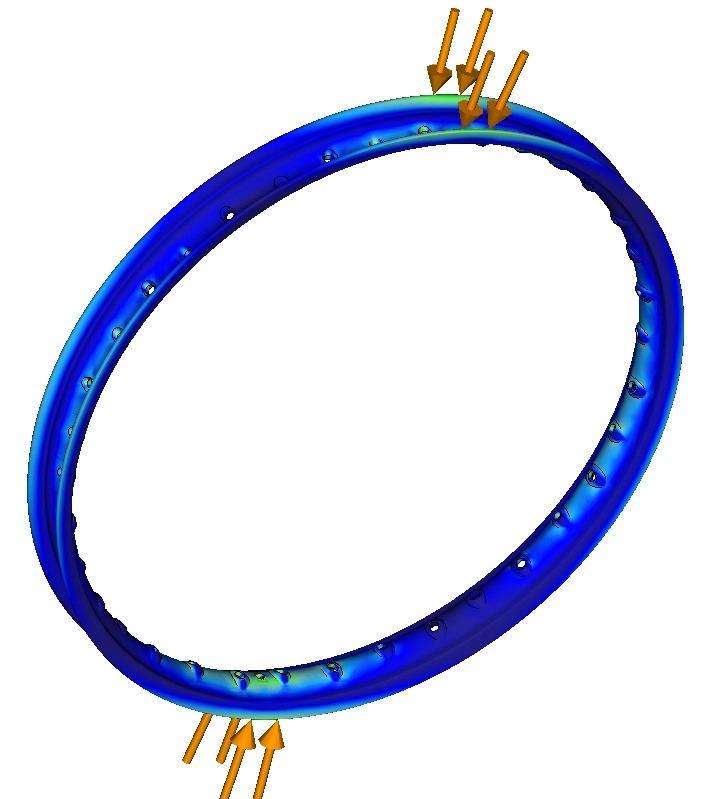

CAE (Computer Aided Engineering) Analysis

We utilize CAE (Computer Aided Engineering) to design the optimum profile of our products.

Thereby, we enhance the performance and quality of our products and provide our customers with the best products possible.

Product Development Examples

Using prototype rims, we conduct actual driving tests by contracted riders.

In these tests, we examine not only strength, but also handling and other improvements to enhance product quality and performance.

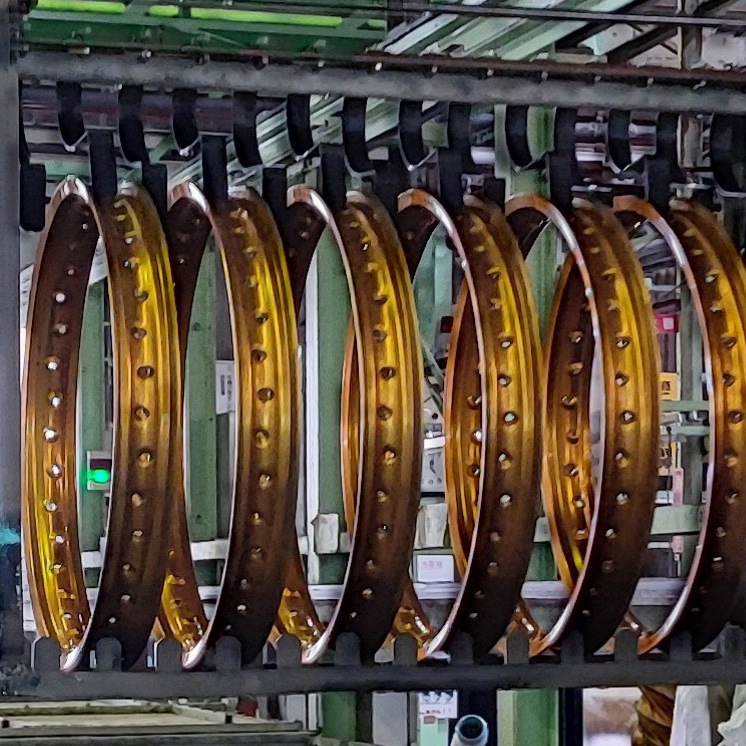

Aluminum Rim Manufacturing System

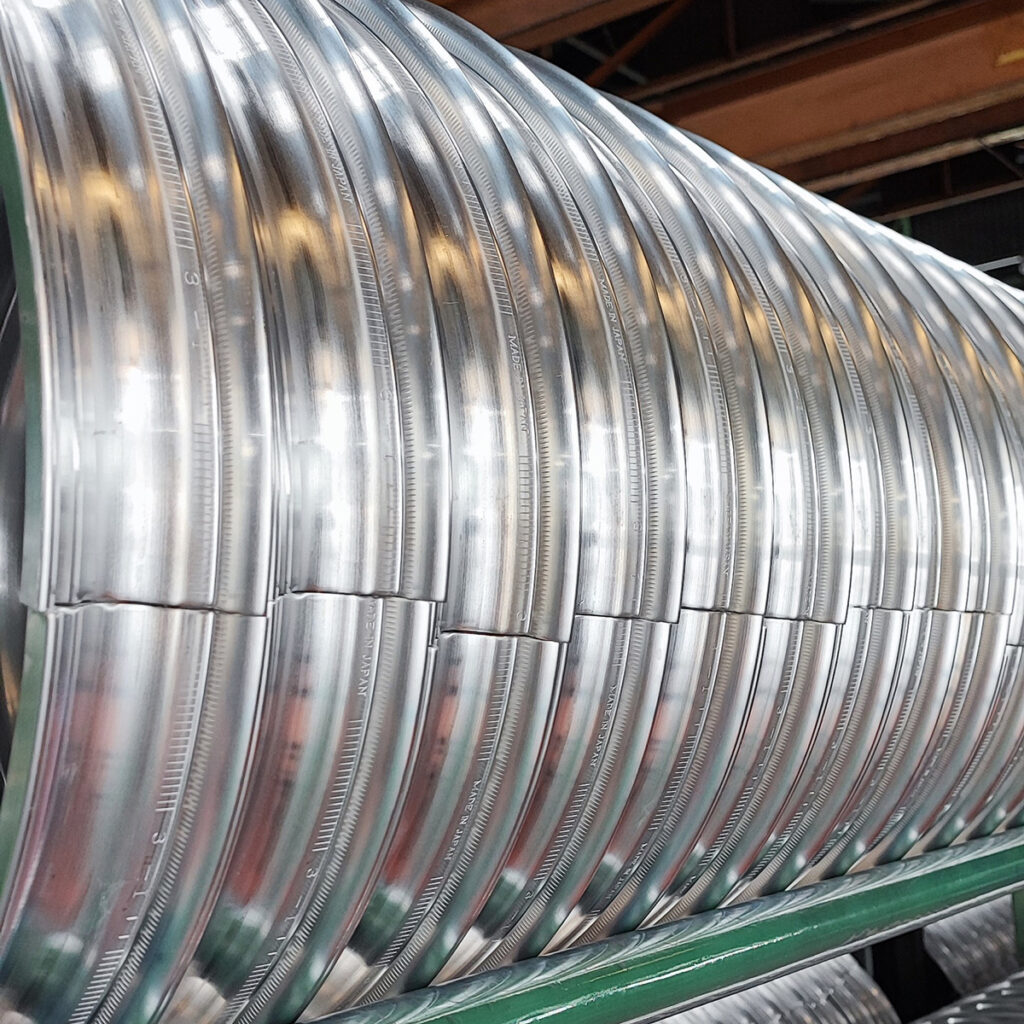

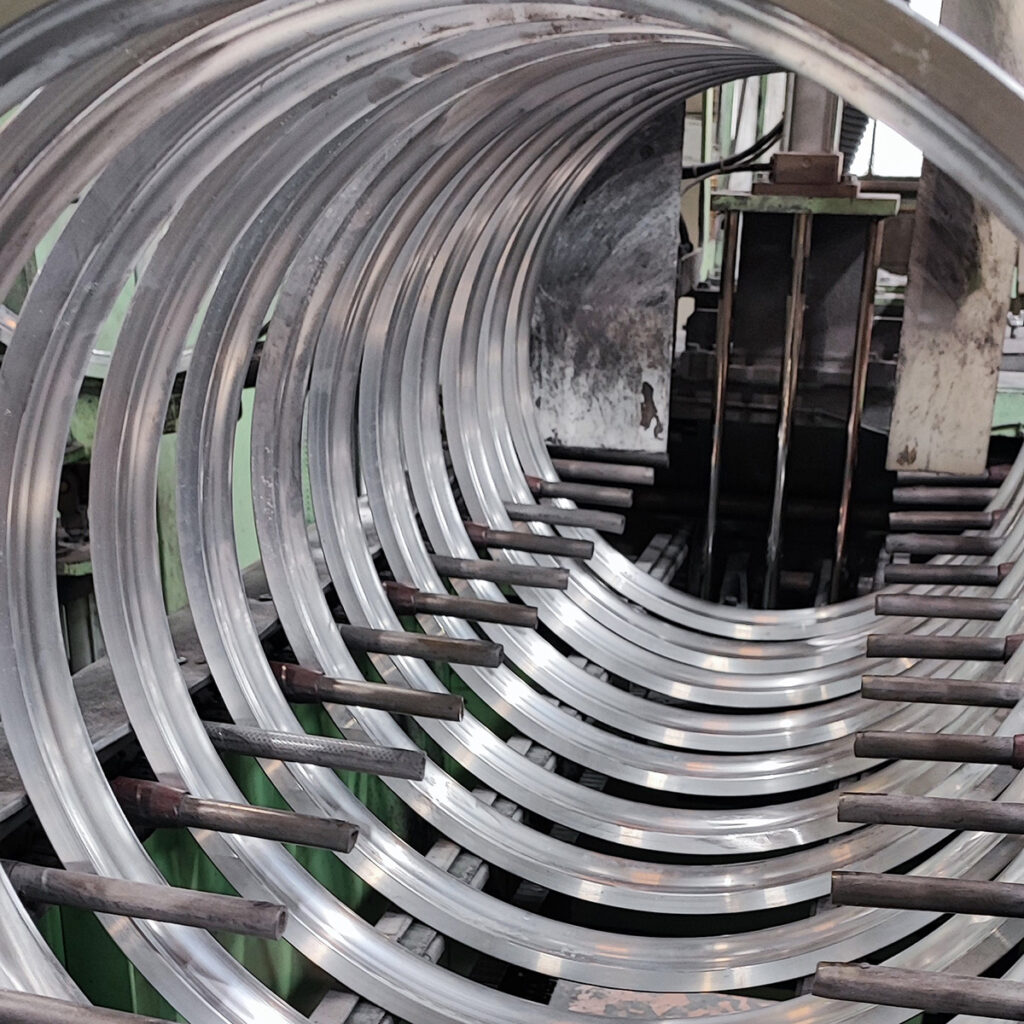

We have a lot of technology related to the manufacturing of aluminum rims, and we handle the entire manufacturing process in house.

This enables us to provide the highest quality products based on strict quality control to our customers.

Manufacturing process of aluminum rim

Forming

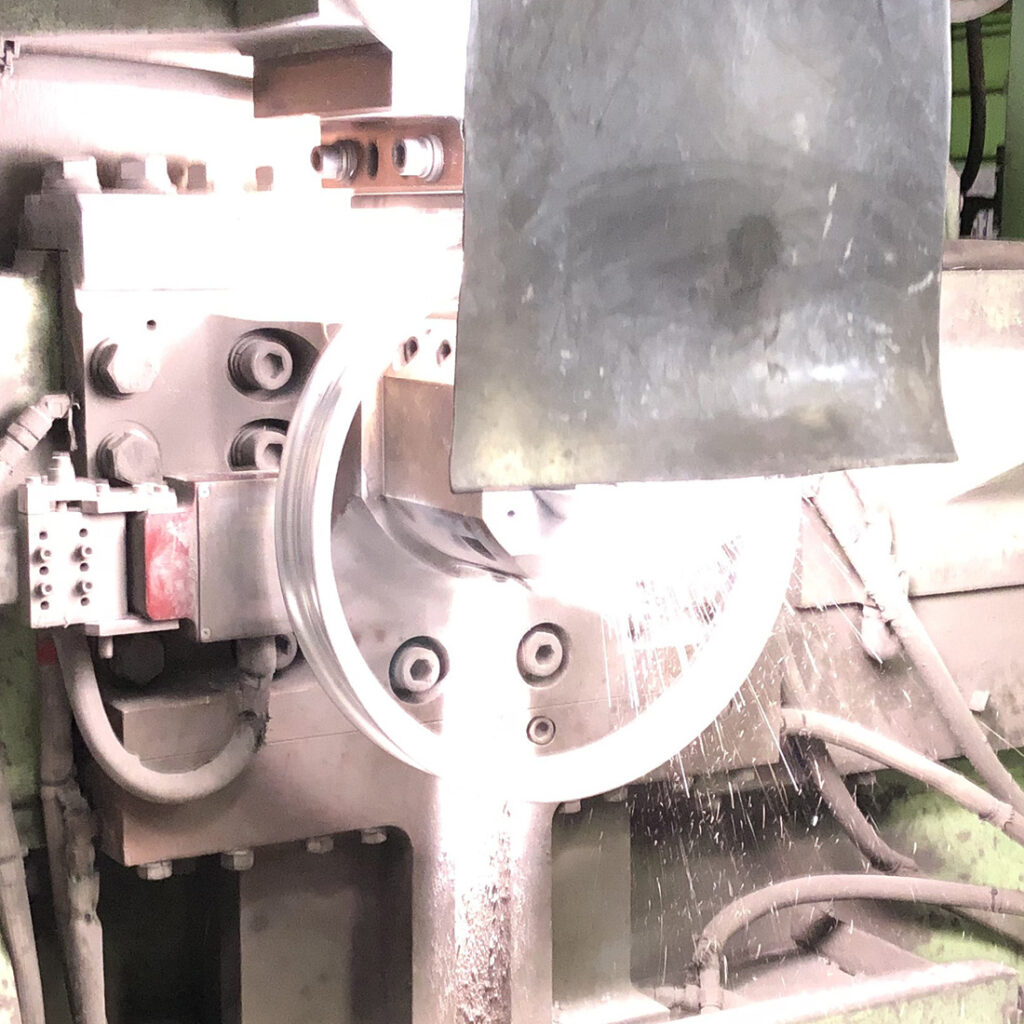

Aluminum alloy extrusions are adjusted and processed to the dimensions of the product.

Welding

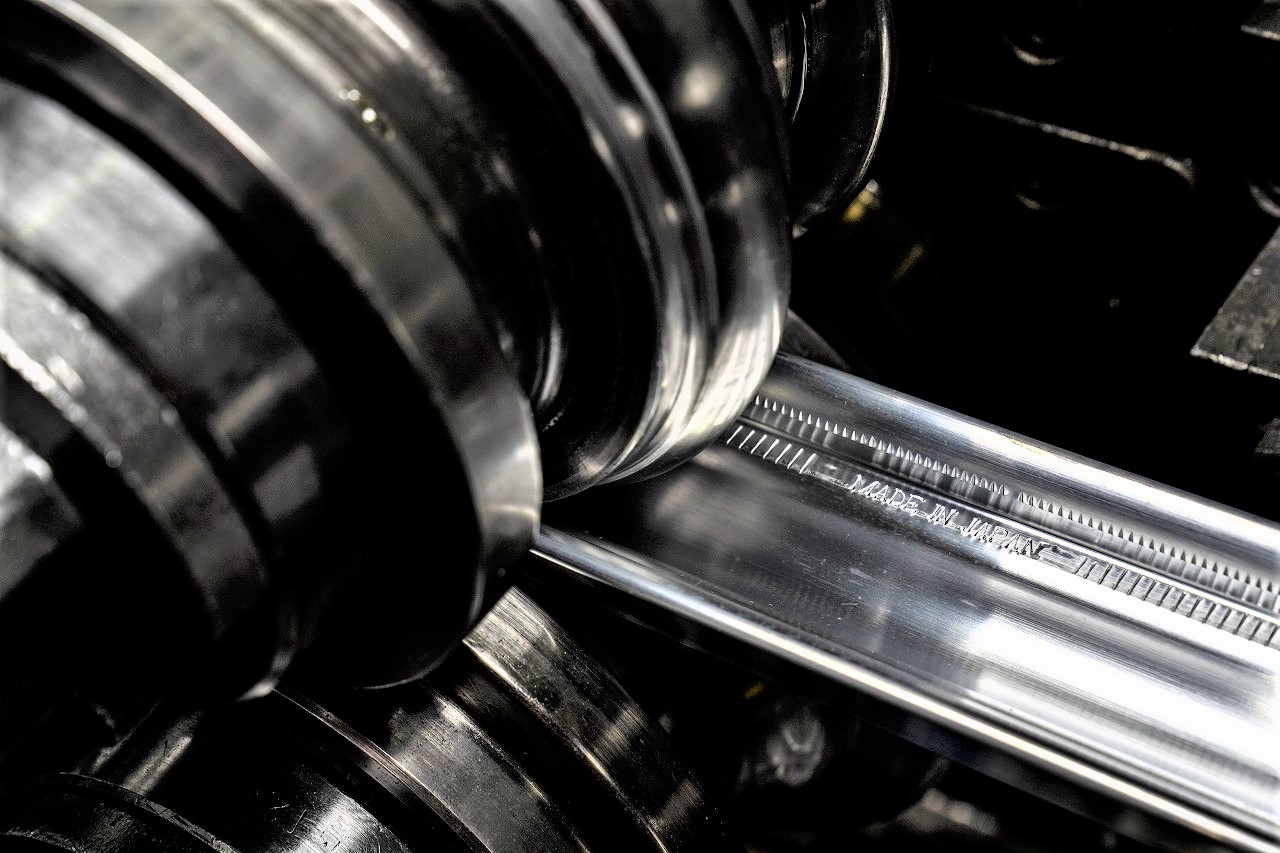

Special welding technology is used to ensure high strength that cannot be obtained by other methods.

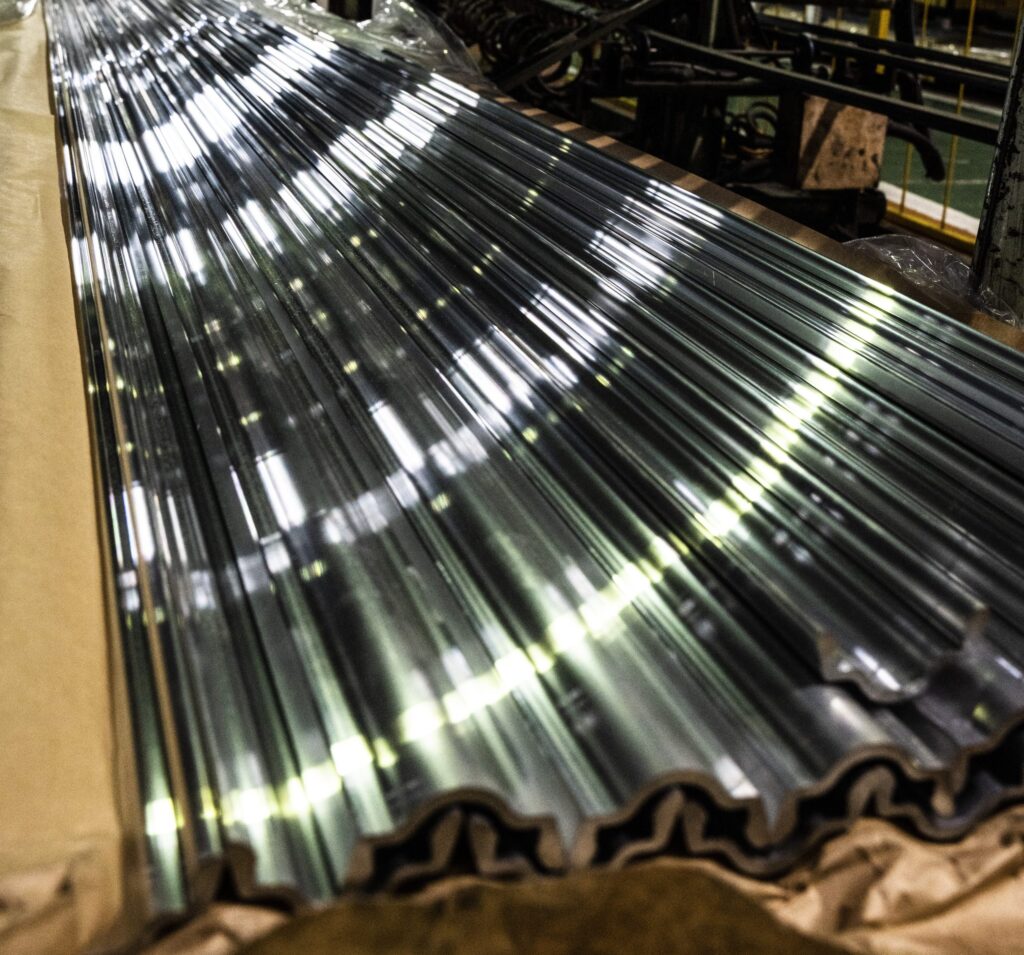

Polishing

Mirror finish, one of the features of our products, is achieved through multiple polishing processes.

Heat Treatment

Special treatment maximizes the strength and flexibility of aluminum alloys.

Press

Using special equipment to make dimples so that nipples can be fitted properly, as well as to punch holes with angles and diameters to suit each model.

Surface Treatment

A process called anodizing creates an oxide film on the aluminum surface, which makes corrosion more difficult.

Various colors can be applied and logos are added in this process.